Ultra-narrowband filters are widely used in narrow linewidth lasers, Raman spectrometers, fluorescence microscopes, ultrafast spectroscopy, attosecond lasers, fiber-optic communication networks, aerospace and other scenarios.

Auxcera uses ion beam sputtering coating and magnetron sputtering coating technology to produce ultra-narrowband optical filter products. Currently, we can manufacture flat-top and Gaussian filters with a half-width of 0.3nm in the near-infrared band and a half-width of 1nm in the visible light band.

*Center Wavelength Uniformity and Processing Capability:

*1 inch, the best center wavelength uniformity level is +/-0.15nm, half inch, center wavelength uniformity level is generally less than +/-0.1nm

*1020-1100nm, 1260nm-1650nm can realize the processing of 0.3nm half-width filter, 400-1700 can realize the processing of 1nm half-width filter

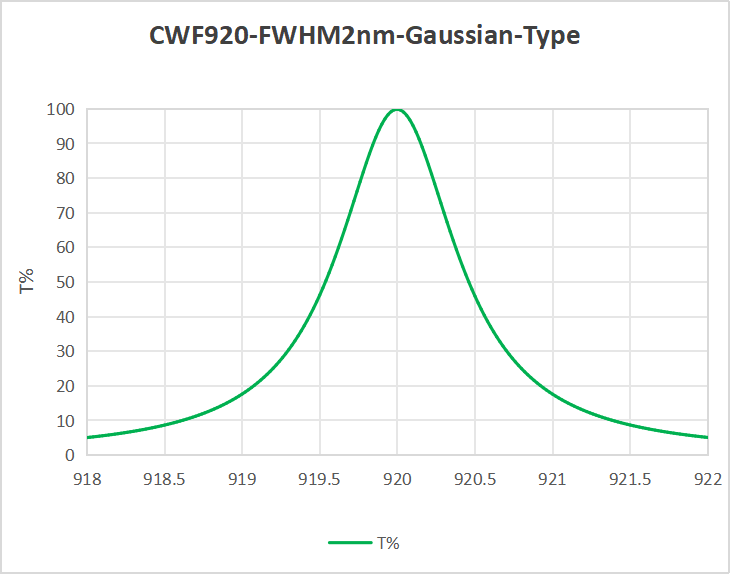

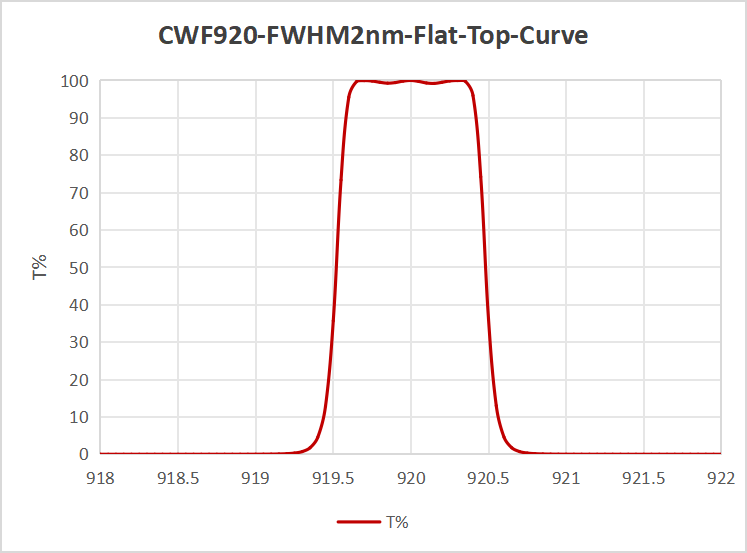

Difference between flat-top and Gaussian filters:

From the perspective of filter preparation: flat-top filters have higher preparation difficulty

From the perspective of filter use, flat-top filters can achieve higher power output based on the same power light source in the target center band, and the output light is also purer, without so much stray light interference

*Lead Time:

3-4 weeks for customized products

*Price:

FWHM 0.3/1nm: Customize one run, 4 piece 1-inch or 8 piece half-inch (contact sales for accurate quotation)

FWHM 2nm and above: Customize one run, 4 piece 1-inch or 8 piece half-inch (contact sales for accurate quotation)

*Notes:

*Blue shift of the filter. For customers who apply it to laser filtering, the filter generally has a blue shift phenomenon, that is, when light is incident on the filter from a larger incident angle, the center wavelength of the filter will shift to the short-wave direction. Therefore, customers who generally use narrow linewidth lasers should set the center wavelength of the filter to be about 0.5nm longer than the original center wavelength when setting the center wavelength of the filter. This is more appropriate, because when the filter adjusts the incident angle, the center wavelength will only shift to the left, not to the right.

Processing Process:

*Customers provide central wavelength, half-height width, cut-off band range on both sides, filter size requirements, thickness requirements (default 1mm if no requirements)

*Our company simulates the specification and filter spectrum data according to customer requirements

*Customers confirm the specification

*Our company processes and manufactures and arranges delivery

Currently completed projects (contact sales for accurate quotation):

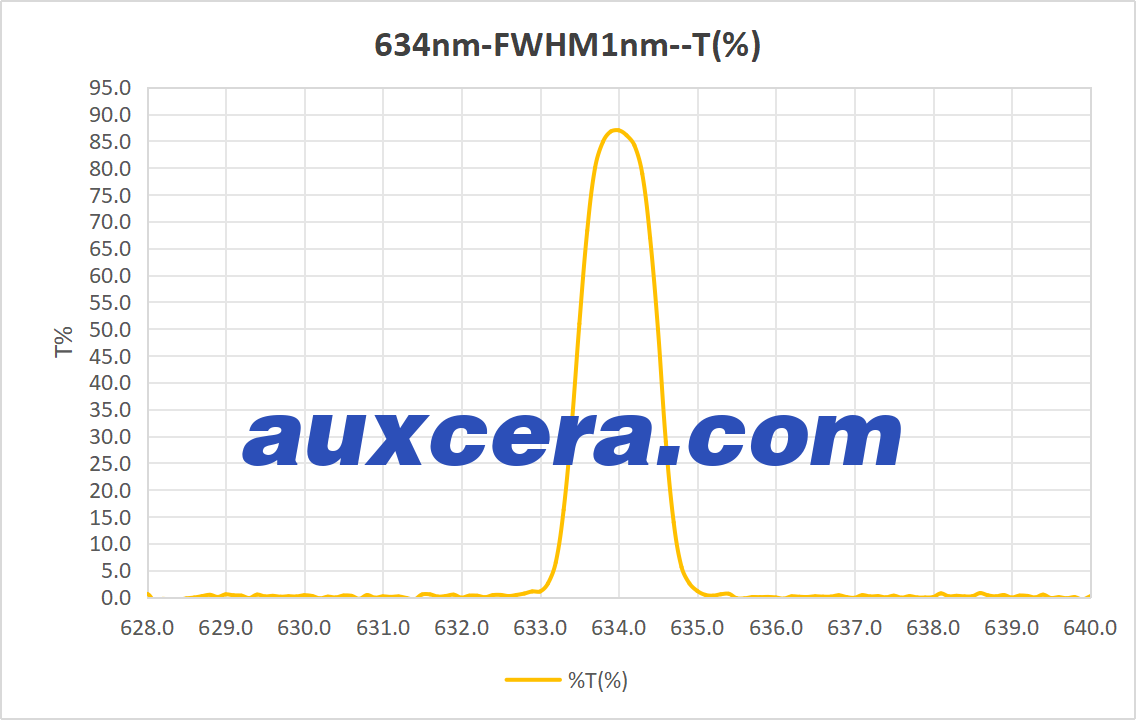

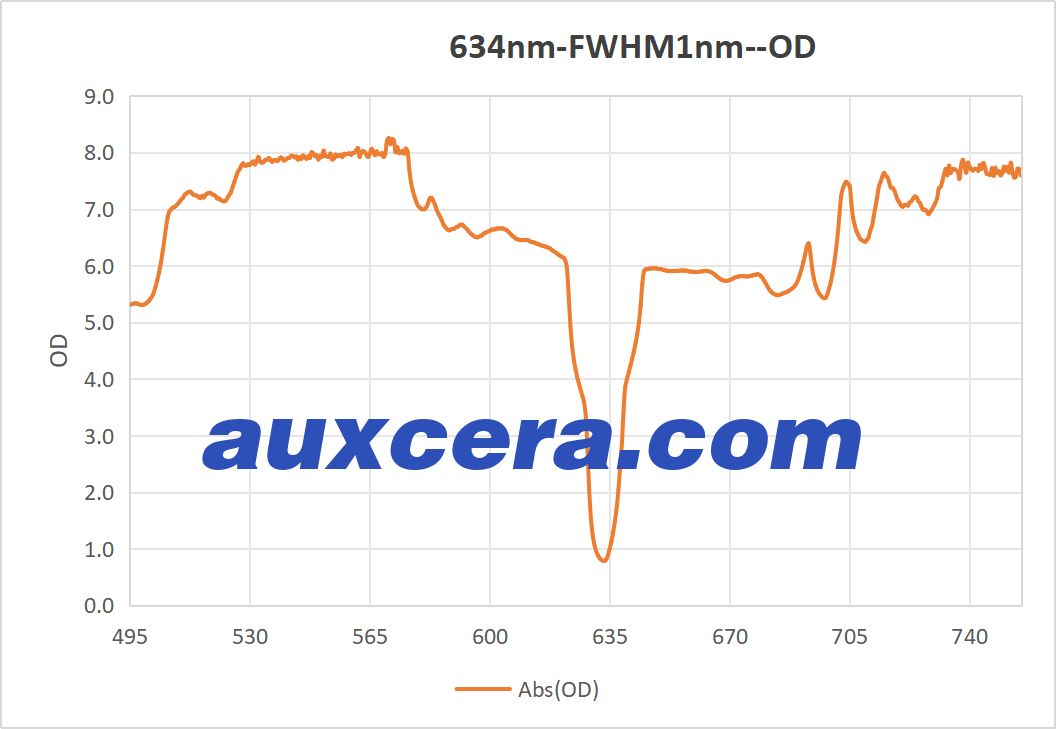

634-FWHM-1nm

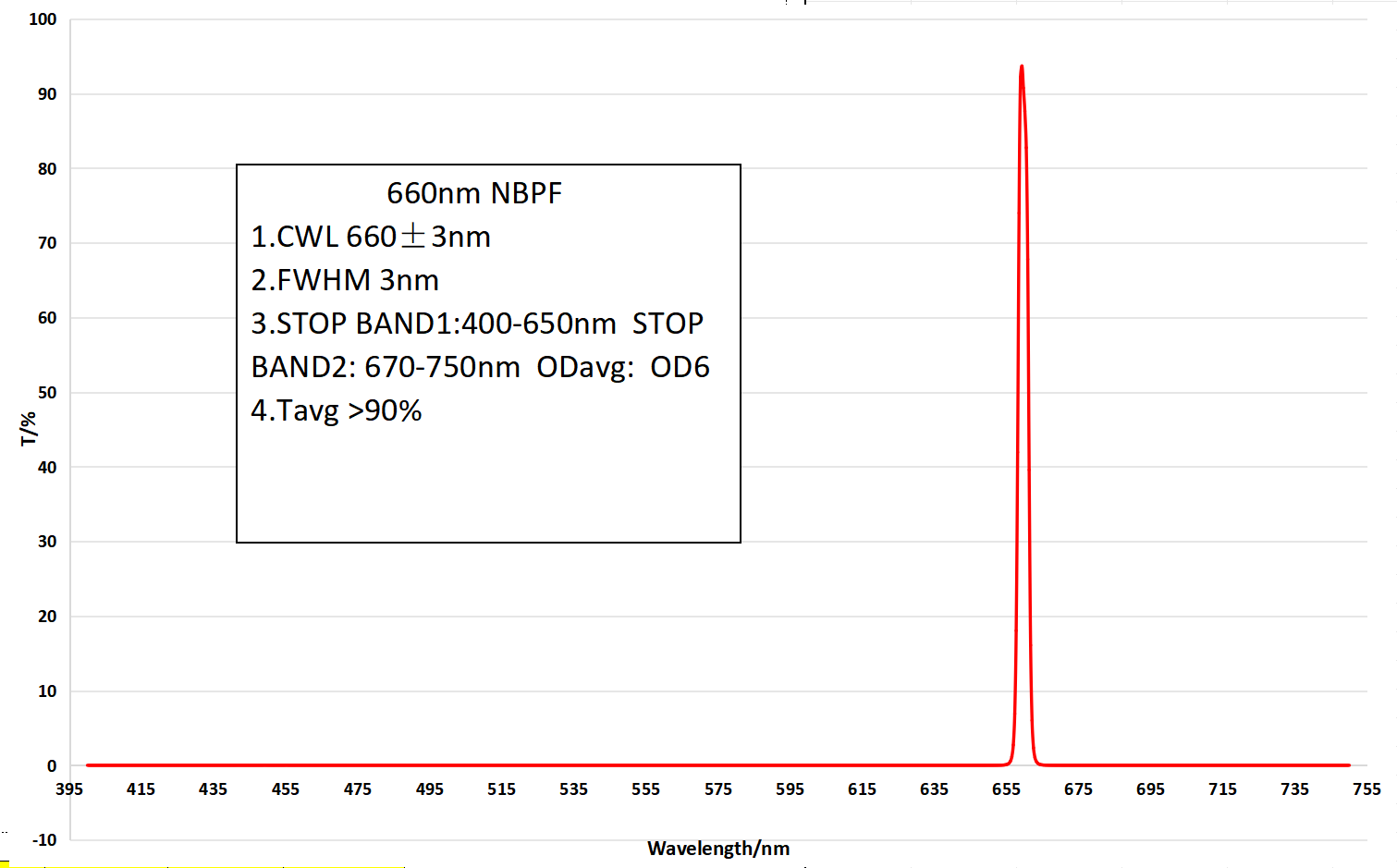

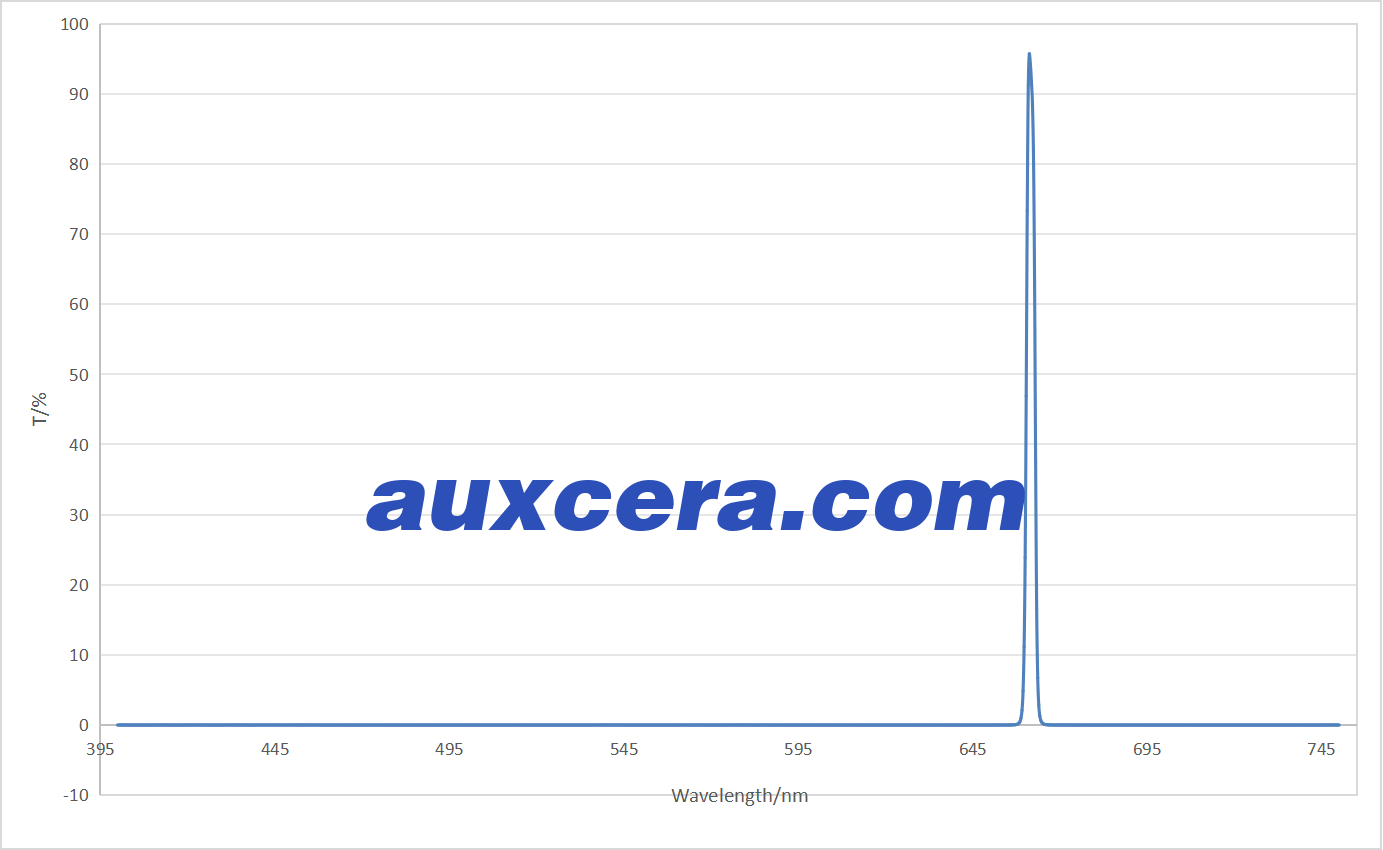

660-FWHM- 3nm

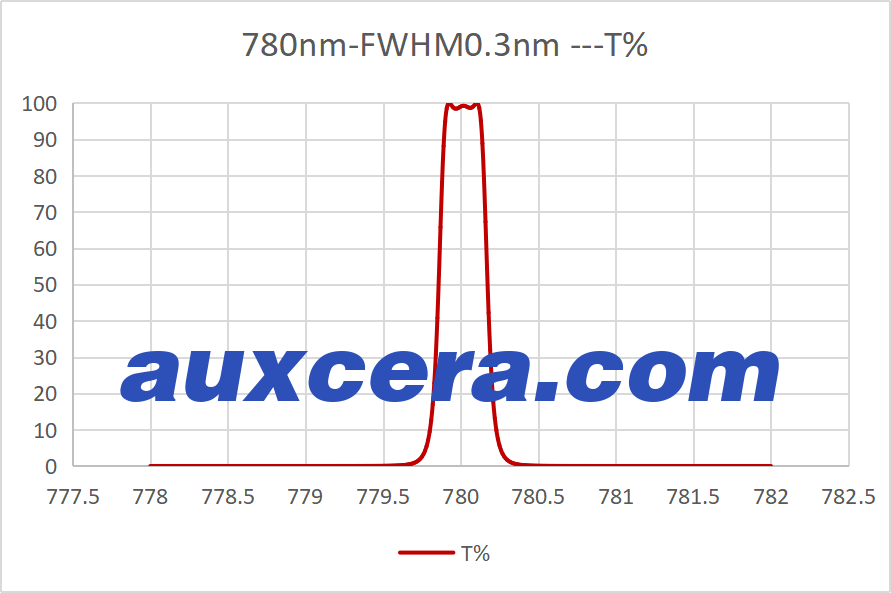

780-FWHM- 0.3nm

795.1-FWHM- 1nm

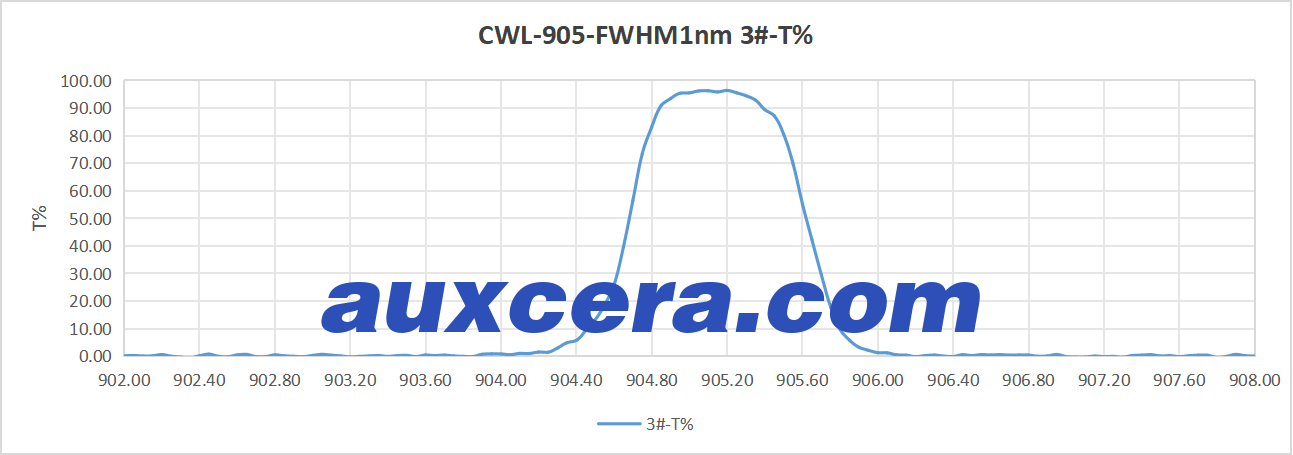

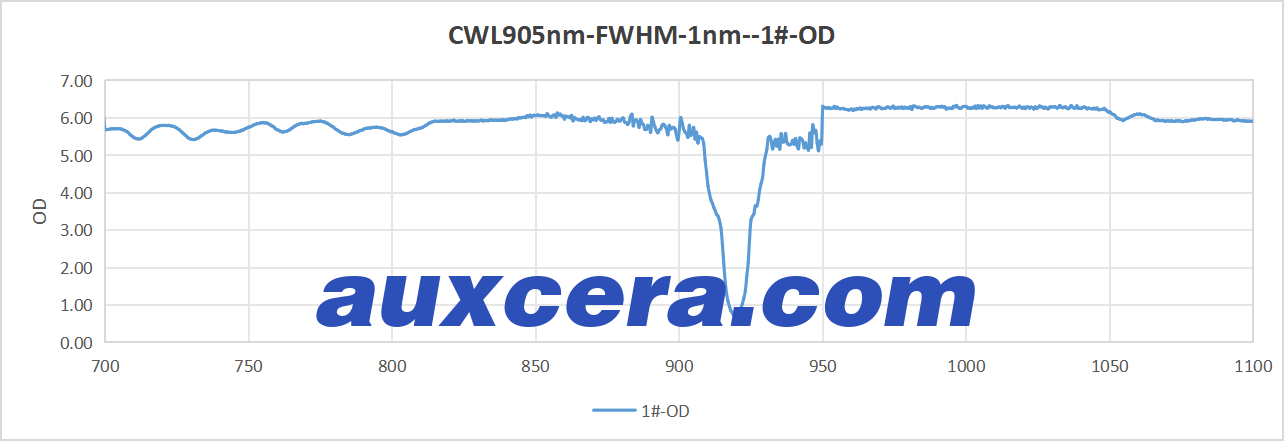

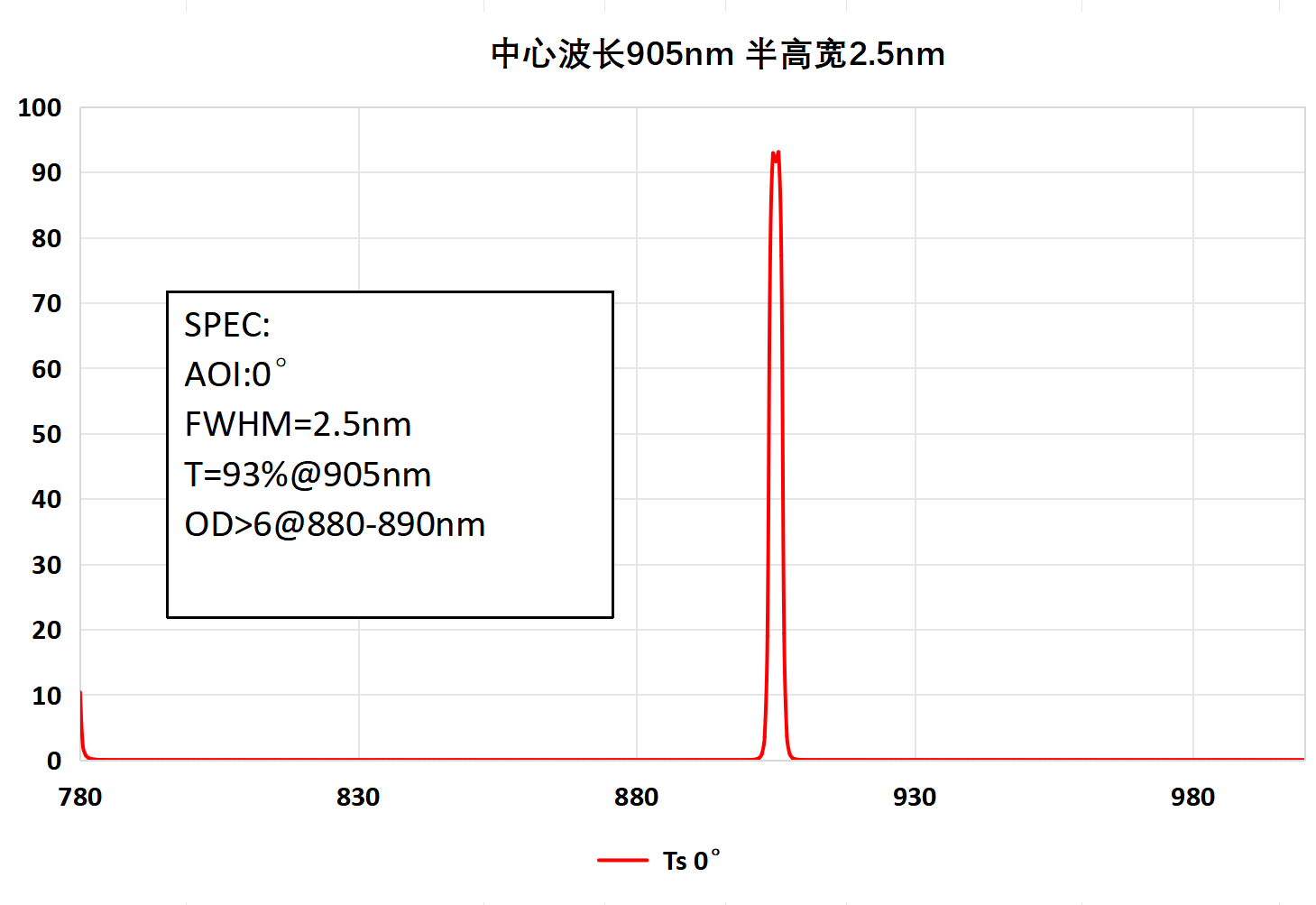

905-FWHM- 1nm

920-FWHM- 1nm

1030-FWHM-1nm

1030-FWHM- 0.3nm

1064.5-FWHM- 1nm

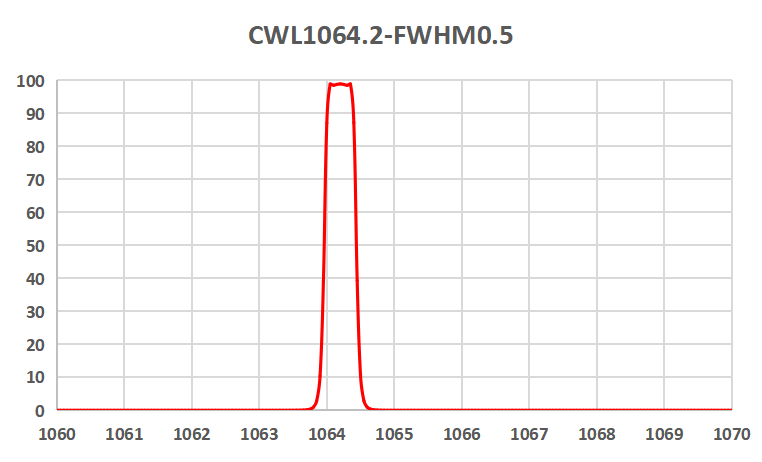

1064.5-FWHM- 0.5nm

1064.5-FWHM-0.3nm

1270-FWHM-0.3nm

1550-FWHM- 0.7nm

1560-FWHM- 0.3nm

CWL1064.2nm--FWHM0.3nm

CWL--634nm--FWHM1nm

CWL--780nm--FWHM0.3nm

CWL--905nm--FWHM1nm

CWL660nm--FWHM2.5nm

CWL532nm--FWHM0.5nm

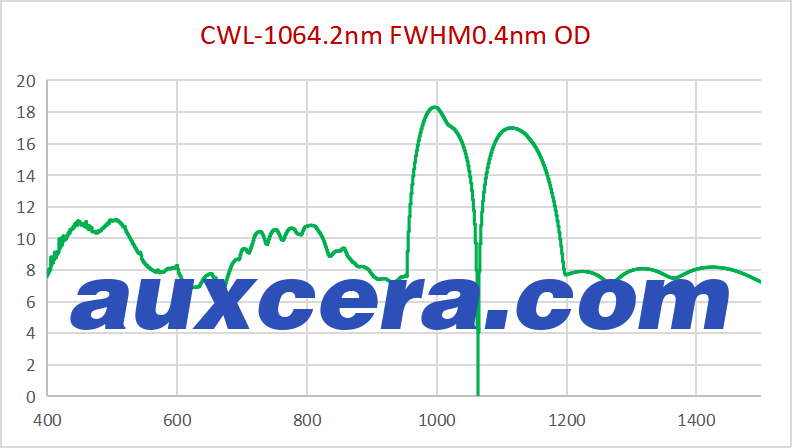

CWL1064nm--FWHM0.4nm

CWL905nm--FWHM2.5nm

Auxcera (Shanghai Taoteng Electronic Technology Co., Ltd.) was founded in 2022. The company is located in Baoshan District, Shanghai. It has R&D centers in Zhongshan and Shenzhen, covering an area of 1,000 square meters and currently has more than 50 employees.

The company's founding team comes from top domestic universities, research institutes and well-known overseas coating companies, including 2 doctors in optical thin films. We focus on the development of semiconductor and optical thin film processes. Relying on multiple types of advanced coating equipment (Vecco Spectra/ion beam sputtering coating, North Huachuang B630/vacuum evaporation coating, Ulvac/continuous magnetron sputtering coating, Optorun OWLS magnetron sputtering coating, Beneq/atomic layer deposition), advanced detection equipment (SEM, AFM, four-probe, ellipsometer, Agilent Cary 7000, Zygo MST interferometer), we provide reliable and high-performance coating services for semiconductors, consumer electronics, AR/VR, instruments, lidar and other fields.