Shanghai Taoteng provides metal film reflector (gold, silver, and aluminum) and dielectric film reflectors (from ultraviolet to mid-to-far infrared), especially specializing in ultraviolet band and high-power reflectors.

At the same time, it should be pointed out that we have received many customers' inquiries about DBR reflectors. DBR reflectors in the optical industry are optical dielectric film (oxide) reflectors. You only need to tell us which band you need to reflect, and we can give you a coating design.

Stock:

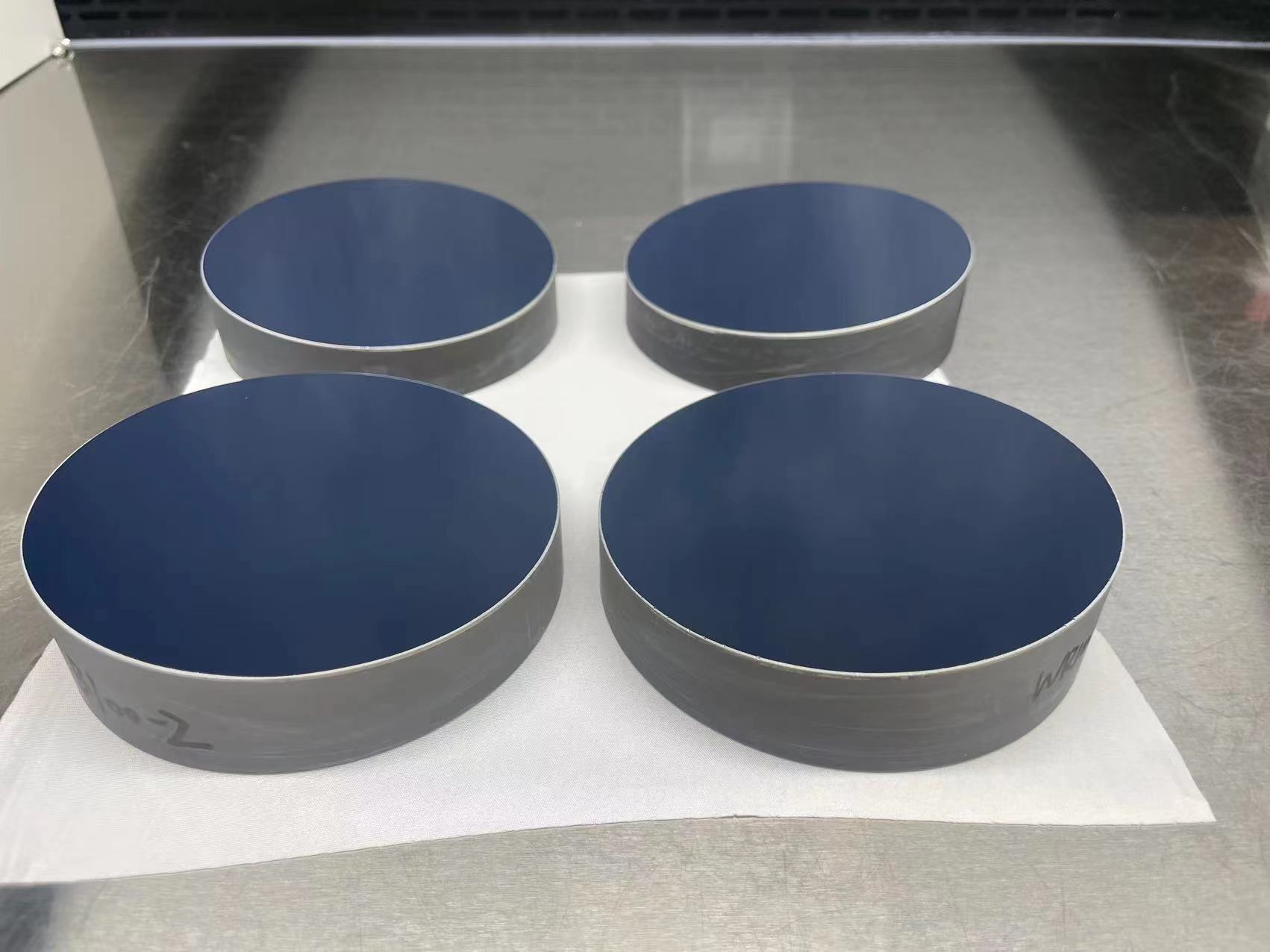

Gold-plated reflectors

Silver-plated reflectors

Aluminum-plated reflectors

0° high damage 1064nmHR, 25mm 5 pieces;

45° high damage 1064nmHR, 25mm 5 pieces;

45° 266HR 532&1064AR 25mm 16 pieces;

45° 355HR 532AR 12.7mm 5 pieces, 25mm

45° 193nm UV Reflector

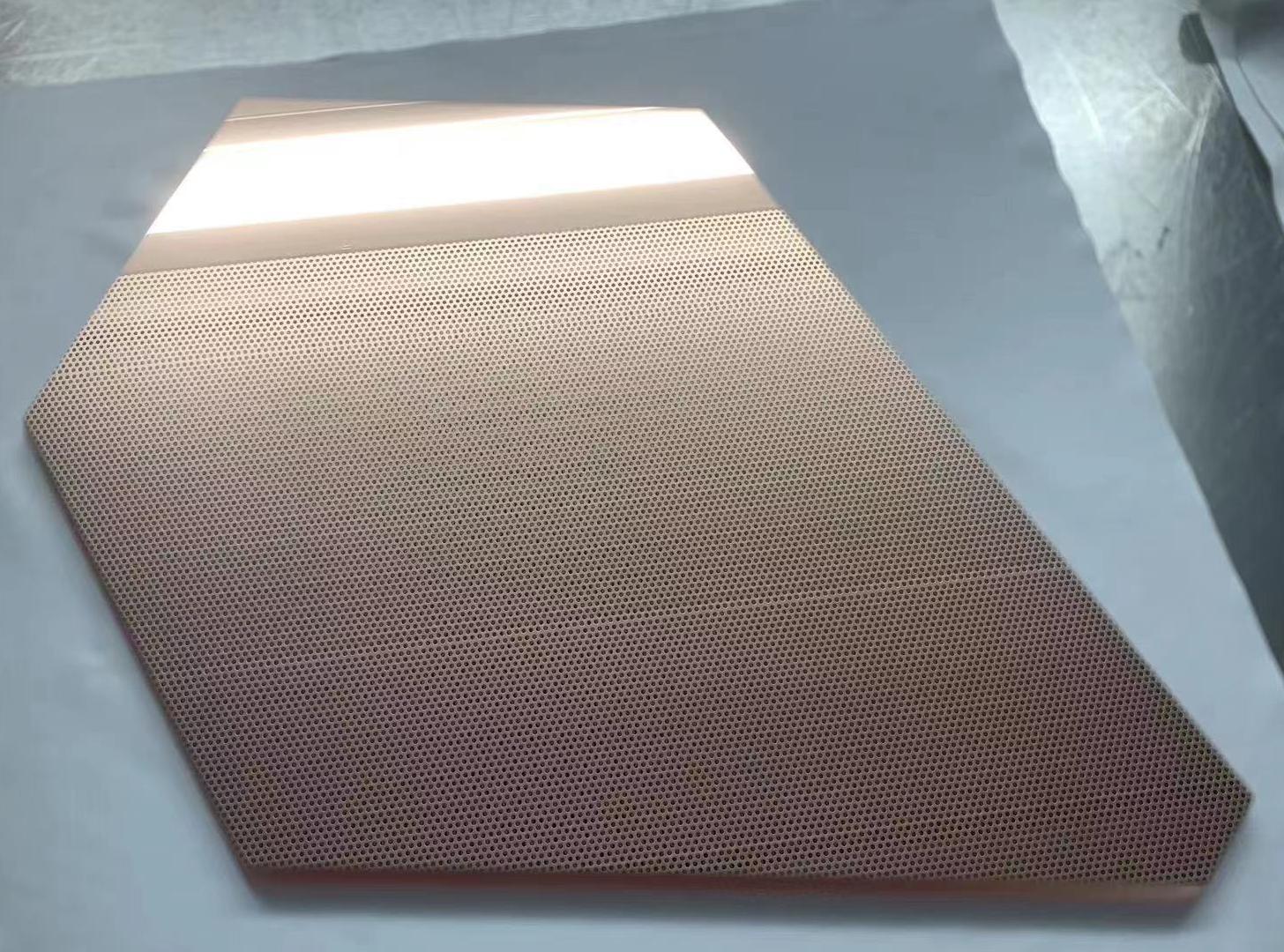

Dielectric film reflector: An optical reflector realized by multi-layer oxide. The principle is based on the interference effect of light. The thickness of the oxide stack is designed to achieve the reflection of a certain band of light. The commonly used stacking materials are SiO2/Ta2O5 and SIO2/HfO2. At the same time, these two materials absorb less light and can achieve the reflection of high-power lasers.

Features: It has a relatively high reflectivity for a certain wavelength of light and is sensitive to the incident angle of light. The reflectivity of the reflector changes with the angle of the incident light.

Metal film reflector: Generally, the metals are gold, silver and aluminum. The reflectivity of the material itself is used, and it is not so sensitive to the incident angle of light. Gold is suitable for the near-infrared band, silver is suitable for the visible light band, and aluminum is suitable for the visible light and ultraviolet bands.

Magnetic control sputtering is used to plate metal gold, silver, copper, aluminum, chromium, titanium, nickel, etc. The maximum processing size can reach 500mm, the uniformity is better than ±5%, and the environmental testing meets the requirements. The thin films made by our institute have the advantages of good adhesion, high reflectivity, friction resistance, and strong environmental adaptability. They can be widely used in military and civilian optoelectronic equipment such as lasers and optical system components.

In addition to depositing metals with high adhesion and high reflectivity on the surface, we can also deposit a layer of inorganic oxide on the surface to prevent the metal surface from being scratched or oxidized.

Gold-plated reflector

Ag Coated Reflective mirror

Al Coated Reflective mirror

Cu Coated Reflective mirror

Auxcera (Shanghai Taoteng Electronic Technology Co., Ltd.) was founded in 2022. The company is located in Baoshan District, Shanghai. It has R&D centers in Zhongshan and Shenzhen, covering an area of 1,000 square meters and currently has more than 50 employees.

The company's founding team comes from top domestic universities, research institutes and well-known overseas coating companies, including 2 doctors in optical thin films. We focus on the development of semiconductor and optical thin film processes. Relying on multiple types of advanced coating equipment (Vecco Spectra/ion beam sputtering coating, North Huachuang B630/vacuum evaporation coating, Ulvac/continuous magnetron sputtering coating, Optorun OWLS magnetron sputtering coating, Beneq/atomic layer deposition), advanced detection equipment (SEM, AFM, four-probe, ellipsometer, Agilent Cary 7000, Zygo MST interferometer), we provide reliable and high-performance coating services for semiconductors, consumer electronics, AR/VR, instruments, lidar and other fields.