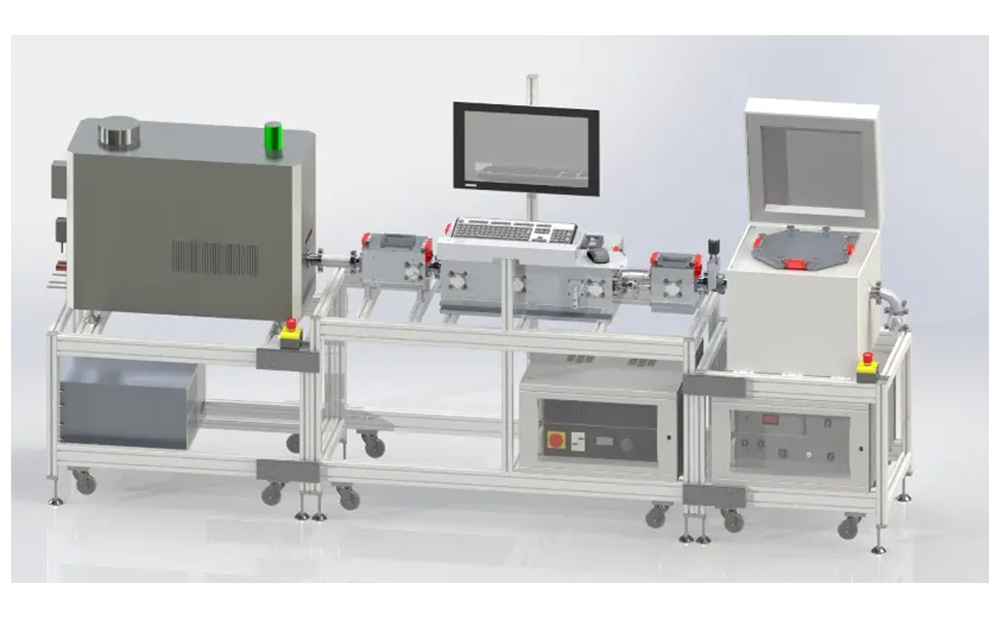

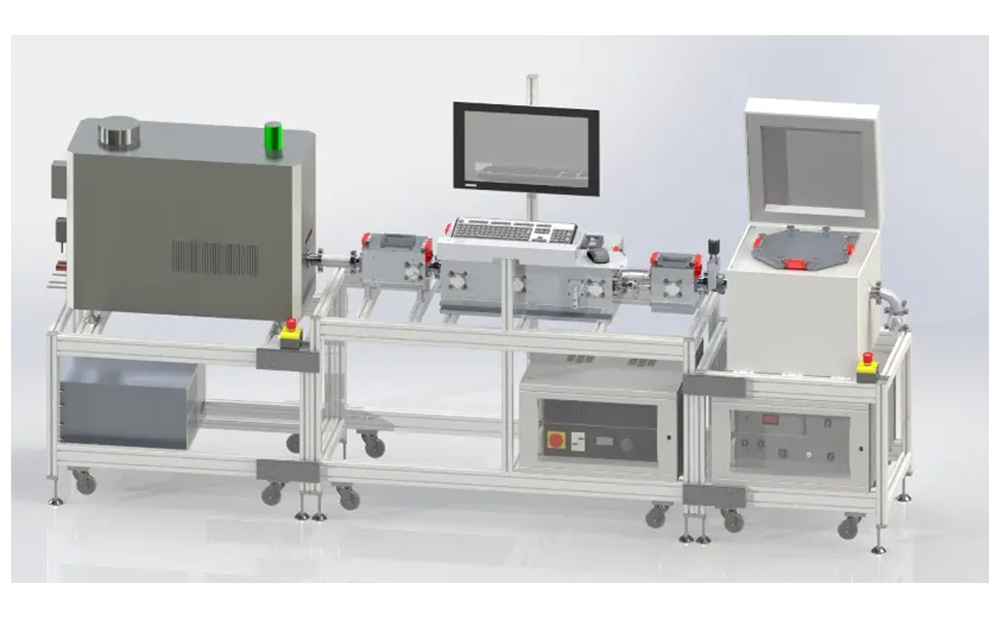

Relative Weak Absorption Tester

Brand: LZH

Model: PCI-TR

Function: It can be tested with conventional wavelength (1064nm) or customized wavelength, and can test square or circular samples with sample size of 3×3×3~50×50×50 (mm);

Sensitivity: Volume absorption: 1ppm/cm; Surface absorption: 1ppm (one measurement

can be distinguished);

Test speed: conventional 2min/piece (relative to 6mm thickness)

By measuring the absorption and temperature rise data of the film, it can be determined how much the film is affected by a laser of a specific wavelength.

The absorption is measured by a relative weak absorption tester (PCI-TR), and the film layer on the surface of the lens is processed by a 1064nm (or 1030nm) pump light, and the thermal lens effect formed by the film layer is detected by a 632nm detection light. The relative weak absorption value of the film is calculated by processing the detection data. Through long-term technical accumulation, the absorption value of the anti-reflection film can be <3ppm, and the absorption of the multilayer film (layer>30) can be <5ppm.

Temperature rise measurement is a measurement method that characterizes the temperature change after film absorption, which is more in line with actual application scenarios. The measurement uses a 1070nm laser, the test power is 9kW, the average power density acting on the lens is 46kW/cm2, the lens film to be measured is processed for 60s, and the temperature of the laser action area is measured using an infrared camera. The temperature rise data is obtained by subtracting the initial temperature of the lens from the highest temperature. Through long-term technical accumulation, the film temperature rise value can be less than 5℃.

Auxcera (Shanghai Taoteng Electronic Technology Co., Ltd.) was founded in 2022. The company is located in Baoshan District, Shanghai. It has R&D centers in Zhongshan and Shenzhen, covering an area of 1,000 square meters and currently has more than 50 employees.

The company's founding team comes from top domestic universities, research institutes and well-known overseas coating companies, including 2 doctors in optical thin films. We focus on the development of semiconductor and optical thin film processes. Relying on multiple types of advanced coating equipment (Vecco Spectra/ion beam sputtering coating, North Huachuang B630/vacuum evaporation coating, Ulvac/continuous magnetron sputtering coating, Optorun OWLS magnetron sputtering coating, Beneq/atomic layer deposition), advanced detection equipment (SEM, AFM, four-probe, ellipsometer, Agilent Cary 7000, Zygo MST interferometer), we provide reliable and high-performance coating services for semiconductors, consumer electronics, AR/VR, instruments, lidar and other fields.